Mueller Electric provides technical and design expertise to many projects. Our Supervisory team is a invaluable resource offering ideas and innovative solutions on a moments notice. The ability to think outside the box with limited resource is key in remote locations. As with all projects Mueller provided the client with a flawless start-up.

Tailing pumps power installation

Mueller Electric provided the installation of the 5kv power feed to the old pit that was being utilized as a tailing pond. The extreme weather and terrain was no obstacle for the Mueller Crew. Faced with critical time lines to ensure continued operation of the mine our crew utilized limited resources to hand manoeuvre 1 km of 5 kv cable weighing 8000 lbs. The project was complete without production loss and allowed the mine to continue operations.

- Commissioned and tested 5kv power skid

- Wired and Powered up pumps

- Heat traced all pipe

- Assembled and wired heat trace controller stations along the tailings line

- Installed cable tray wired VFD Control over the tailings pump

- Using limited resource and tight timelines pulled 8000 lbs of 5kv cable to accommodate installation of power.

Upgrade power feeds and new distribution for new camp

- Communication and fiber for new camp

- Complete all camp interconnections

- Install and commission power for new camp

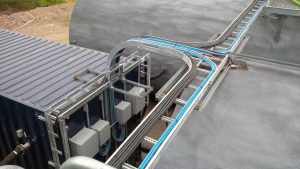

Sewage treatment plant for new camp

- Installation of sewage treatment plant

- Provide power for the plant

- Provide fiber optic communications

- Design and build cable tray runs for foam insulated tanks.

- Interconnection of all power and instrumentation between tanks and main process room.

- Design and install heat trace from septic system into discharge

- Commissioned and set up VFDS for pump station

OTHER PROJECTS ON SITE

- Set up all multilins for power monitoring

- Set up all PDC’s

- Underground ventilation power supply.

- Underground Substation upgrades and maintenance

- 5kv switchgear installation for underground